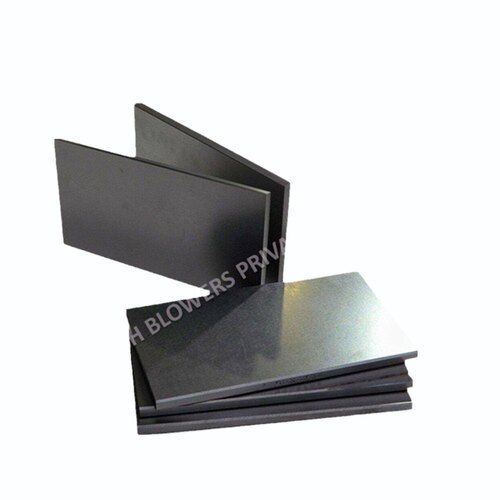

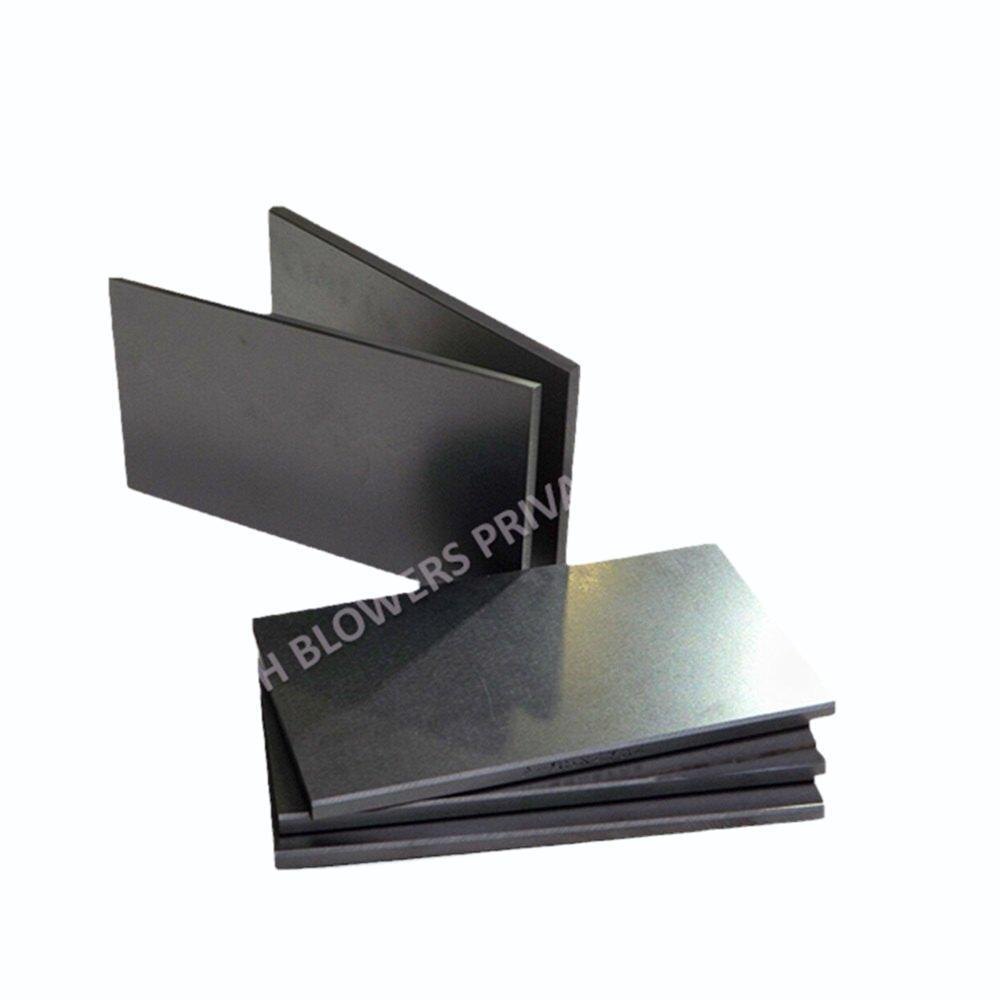

Vacuum Pump Carbon Vanes

15000 INR/Unit

Product Details:

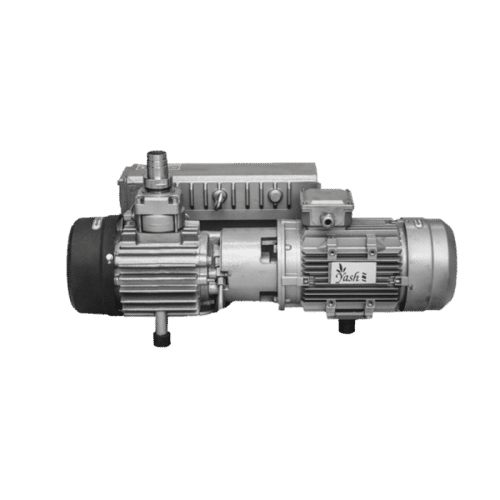

- Theory Vacuum Pump

- Usage Industrial

- Material Carbon Graphite

- Size Standard

- Color Black

- Click to view more

X

Vacuum Pump Carbon Vanes Price And Quantity

- 15000 INR/Unit

- 1 Unit

Vacuum Pump Carbon Vanes Product Specifications

- Vacuum Pump

- Industrial

- Carbon Graphite

- Standard

- Black

Vacuum Pump Carbon Vanes Trade Information

- 100 Unit Per Day

- 3 Days

Product Description

Vacuum Pump Carbon Vanes, manufactured, supplied by us, are widely utilized for integrating with different types of industrial vacuum pumps. These carbon vanes are acclaimed by our clients present in various continents for optimum resistance against corrosion and capability to withstand varied temperature range. Superior-grade raw materials and sophisticated technology are utilized for manufacturing these carbon vanes so as to ensure their durability and high tensile strength. We offer products in different sizes, accurate dimensions and other specifications to ensure their perfect fitting to vacuum pumps.

Vacuum Pump Carbon Vanes Details

| Application Areas | Salient Features |

| In printing industry | Complete dynamic stability |

| Medical applications | Reliable & durable |

| Used in different packaging machines | It is very easy to install |

| Exhaust pumps | Low noise production during operation |

| Fuel & fuel transfer pumps | Easy & low maintenance |

| Useful in pond aeration | Compact body design |

| Oil burner air atomizing systems | Less power consumption, hence low operating cost |

Useful Facts About Company & products:

| Product Name | Vacuum Pump Carbon Vanes |

| Product Type | Available in Pieces |

| Brand Name | YASH Blowers |

| Place of Origin | Faridabad, Haryana, India |

| Minimum Order Quantity | As per customers requirement |

| Cost | Best Offer |

| Certification | Trust Stamp(From Tradeindia) |

| Nature of Business | Manufacturer, Supplier |

| Legal Status of Firm | Partnership Firm |

| Thickness | 3.5 to 39 mm |

| Carbon Content | Upto 99% |

| Chemical Composition | Carbon, Graphite and Ash |

| Density in g/cm3 | Upto 2.00 |

| After-sales Service | On Customer Demand |

| Compressive strength | 30 to 130 Mpa |

| Payment Mode | Cash, Cheque, DD, Online Modes |

| Packaging Detail | Packed in Wooden Carton |

| Delivery Detail | ASAP after order confirmation |

Reliable Carbon Graphite Vanes for Industrial Vacuum Pumps

Our carbon graphite vacuum pump vanes are engineered for optimal durability and efficiency in demanding industrial environments. Designed to endure continuous operation, these standard-size black vanes are favored for their self-lubricating properties and long lifespan. Sourced from a trusted manufacturer and supplier based in India, these components ensure your vacuum pumps perform reliably and require minimal upkeep.

Precision and Performance in Every Application

Each vane is manufactured to precise industry standards, guaranteeing a seamless fit in most industrial vacuum pumps. The superior quality carbon graphite material ensures low friction and resilience under intense workloads, delivering consistent vacuum generation in sectors like automotive, food processing, and pharmaceuticals. Rely on our expertise for robust, high-performance vanes.

FAQs of Vacuum Pump Carbon Vanes:

Q: How are vacuum pump carbon vanes utilized in industrial applications?

A: Vacuum pump carbon vanes serve as essential moving components within the rotor slots of vacuum pumps. Their primary role is to create and maintain the vacuum by forming the seal necessary for air movement, making them indispensable in various industrial processes requiring reliable suction and air displacement.Q: What material are these vanes made from, and why is it suitable?

A: These vanes are constructed from carbon graphite, a material valued for its self-lubricating properties, structural resilience, and minimal friction. This combination guarantees reduced wear and extends the operational life of both the vanes and the pump system, making it an excellent choice for demanding industrial uses.Q: When should vacuum pump carbon vanes be replaced?

A: Replacement of vacuum pump carbon vanes is recommended when the pump shows signs of reduced efficiency, unusual noises, or if the vanes have visibly worn down. Routine inspection during scheduled maintenance helps prevent unexpected breakdowns and sustains pump performance.Q: Where are these carbon vanes primarily supplied from?

A: These carbon graphite vanes are manufactured and supplied by reputable companies in India. As a major supplier, India delivers high-quality vanes to both domestic and international markets, supporting a wide array of industrial sectors.Q: What is the manufacturing process for carbon graphite vanes?

A: The process includes mixing high-purity carbon powder with binding agents, forming the material under high pressure, and then baking it at elevated temperatures. Afterward, the vanes are machined to precise standards, resulting in accurate dimensions and high durability.Q: How are vacuum pump carbon vanes typically installed and used?

A: Installation involves inserting the vanes into the designated rotor slots of the vacuum pump. Once operational, they slide and rotate to maintain airtight seals, supporting the continuous movement of air and providing stable vacuum pressure for industrial tasks.Q: What are the main benefits of using carbon graphite vanes in vacuum pumps?

A: Key advantages include self-lubrication, resistance to wear and corrosion, minimal maintenance requirements, and consistent performance. These benefits collectively enhance the reliability and cost-effectiveness of vacuum pump operations across industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese