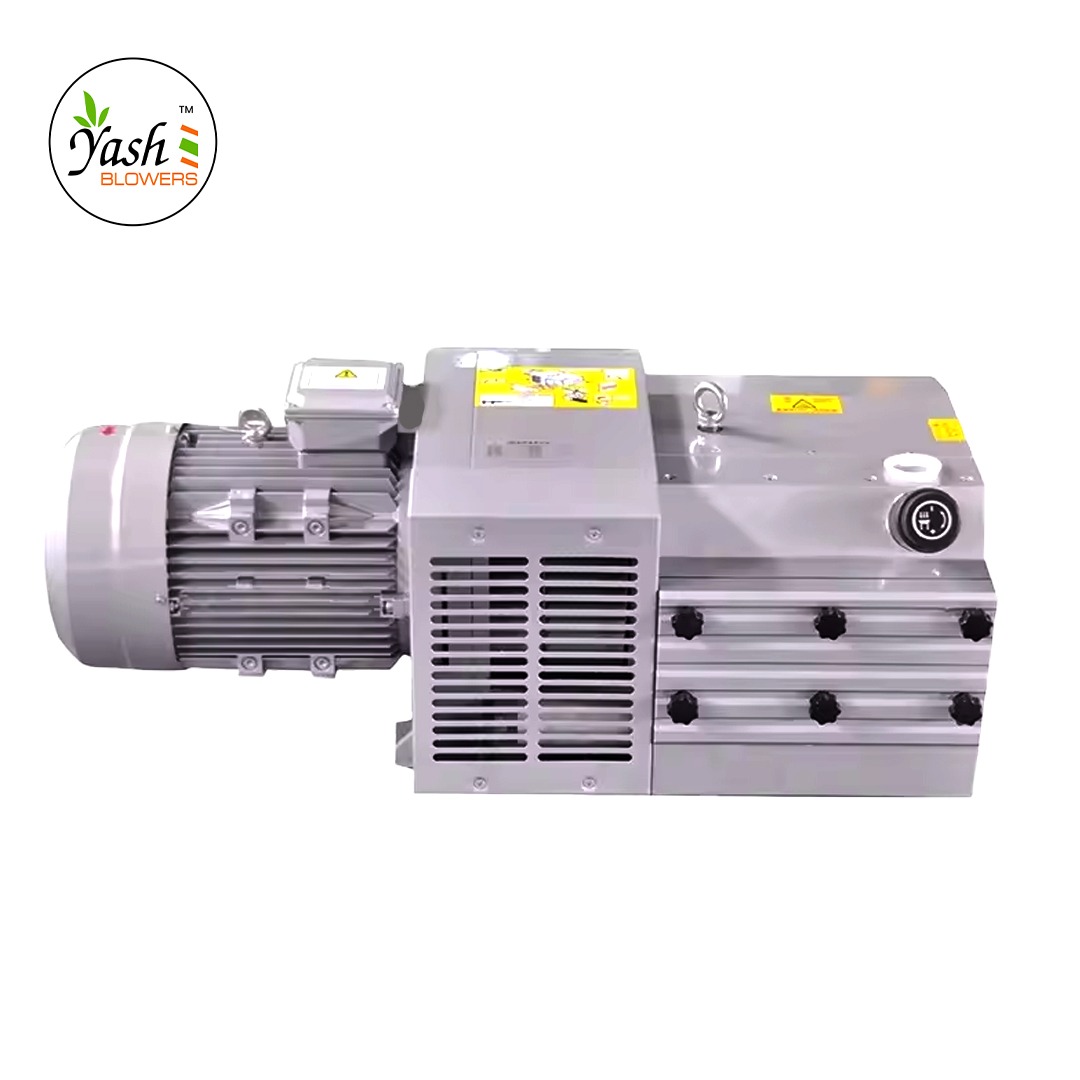

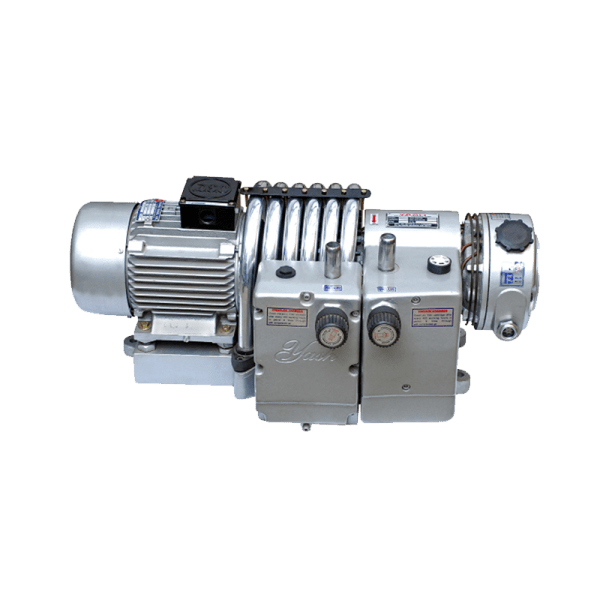

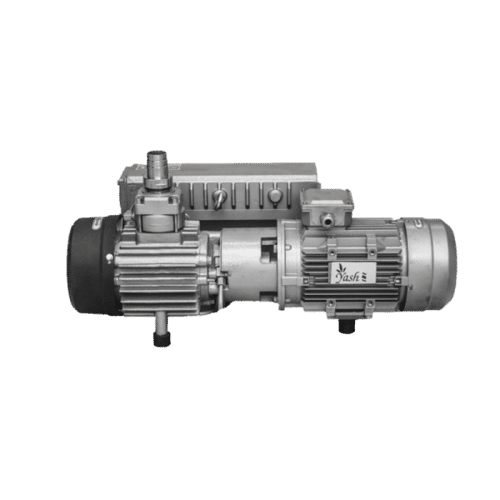

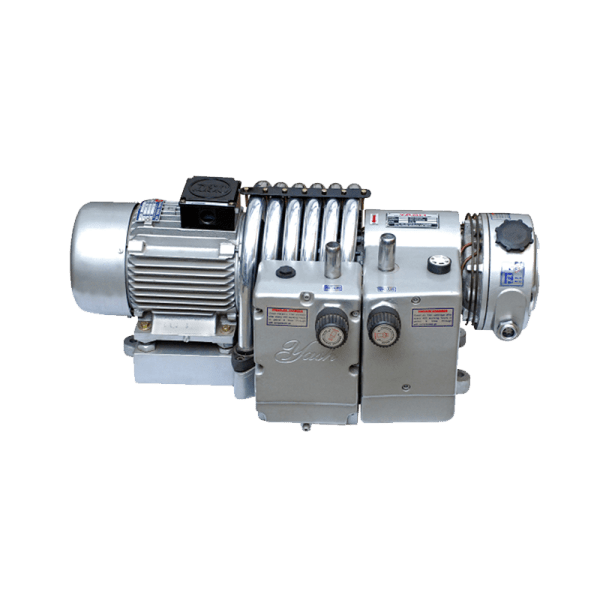

Dry Vacuum Pressure Pump

Product Details:

- Theory Centrifugal Pump

- Material Alluminium

- Structure Diaphragm Pump

- Size Standard

- Product Type Dry Vacuum Pressure Pump

- Color Silver

- Usage Water

- Click to view more

Dry Vacuum Pressure Pump Price And Quantity

- 140000.0 INR/Unit

- 15000.00 - 90000.00 INR/Unit

- 1

Dry Vacuum Pressure Pump Product Specifications

- Diaphragm Pump

- Silver

- Standard

- Centrifugal Pump

- Alluminium

- Dry Vacuum Pressure Pump

- Water

Dry Vacuum Pressure Pump Trade Information

- 100 Per Day

- 3 Days

- All India

Product Description

We have established ourselves as a reliable manufacturer, supplier of Dry Vacuum Pressure Pump. Integrated with oil free pressure valves, lubricated motor and pumps, offered product is acclaimed by customers for its robust construction, prolonged functional life, least operation cost and reliable operations. It is suitably constructed incorporating sophisticated technology so as to make it suitable to ensure a continuous flow of operations. Our clients requirements are of immense importance of us and, to suit their variegated needs, we offer Dry Vacuum Pressure Pump in different models, configurations and other specifications. Get Dry Vacuum Pressure Pump in different specifications. YASH ENTERPRISES in Faridabad is one of the known name in the field of Vacuum Pressure Pumps. Famous for its highly durable & efficient Pumps. Manufactured products are demanded across the world. Customer satisfaction if the main motto of the company. All products are designed & manufactured as per latest industrial standards.

Applications Areas:

- Vacuum Distillation

- Drying

- Filtration

- Glass Blowing

- Bottle Filling

- General Lab Works

- Vacuum Forming

- Blister Packing Machines

-

Technical Specification of Dry Vacuum Pressure Pump:

- Max. Vacuum: 28" of Hg

- Displacement: 9 Cu. mtrs/ Hr

- Power reqd.: 0.5 H.P.

- Vanes: Fiber

-

Physical dimensions available:

- L x B x H (mm): 280 x 178 x 273 (Head Only)

- L x B x H (mm): 445x355 x 330 (with Motor & Base)

- Port Size: 1/4" BSP

Superior Pump Design

Engineered with a diaphragm structure and manufactured from premium aluminium, this pump ensures longevity while minimizing maintenance requirements. Its silver finish underscores its industrial-grade resilience, making it a favored choice in harsh operational environments.

Efficient Industrial Usage

Optimized specifically for industrial water applications, this pump provides consistent vacuum and pressure, contributing to seamless workflows and productivity improvements. Its standard size enables straightforward integration within existing systems.

FAQs of Dry Vacuum Pressure Pump:

Q: How does the diaphragm structure enhance the performance of this dry vacuum pressure pump?

A: The diaphragm structure ensures leak-proof operation and reduces wear during extended use, resulting in more stable vacuum and pressure control. This design is particularly suited for handling liquids like water in demanding industrial environments.Q: What benefits does the aluminium material offer for industrial usage?

A: Aluminium provides the pump with a strong yet lightweight build, leading to enhanced corrosion resistance and improved heat dissipation. This contributes to a longer service life and lower maintenance costs in industrial applications.Q: When is it ideal to use this dry vacuum pressure pump?

A: This pump is ideally used when reliable water handling is required in industrial processes. Its design supports continuous operation in scenarios demanding efficient vacuum and pressure management, such as filtration, drying, or degassing applications.Q: Where can this pump be installed within an industrial setup?

A: The standard size and construction of the pump enable flexible installation in various industrial facilities, such as manufacturing plants, water treatment centers, and processing factories across India.Q: What is the operational process of this centrifugal diaphragm pump?

A: The pump combines centrifugal motion with diaphragm action to create vacuum and pressure. The diaphragm flexes within the pump chamber, drawing in and discharging water efficiently while minimizing the risk of leaks.Q: How can regular usage of this pump benefit industrial operations?

A: Consistent use of this dry vacuum pressure pump enhances process efficiency by providing stable vacuum and pressure, reducing downtime, and supporting overall production reliability in industrial water applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese