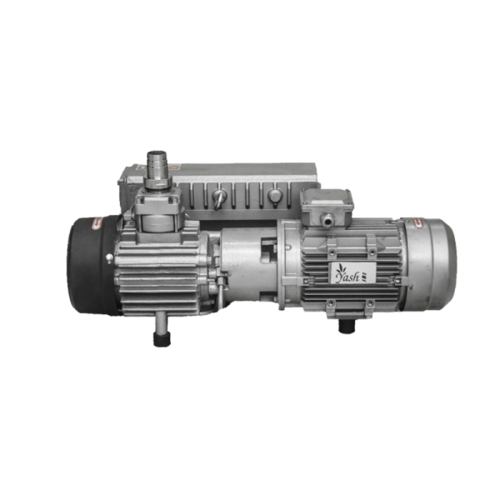

Rotary Vacuum Pump

24500 INR/Piece

Product Details:

- Material Aluminium

- Product Type Vacuum Pump

- Color Silver

- Click to view more

X

Rotary Vacuum Pump Price And Quantity

- 24500 INR/Piece

- 1 Piece

- 24500.00 - 136000.00 INR/Piece

Rotary Vacuum Pump Product Specifications

- Aluminium

- Vacuum Pump

- Silver

Rotary Vacuum Pump Trade Information

- 100 Piece Per Day

- 7 Days

Product Description

We are here manufacturing the high quality rotary vacuum pump that is made for the use in various industrial and commercial applications. It is made of high quality metal and has an effective performance that is long lasting. A vacuum in industries is used for getting the air molecules out and producing a little vacuum. The pump is very high power and has a ling a service life.

Rotary Vacuum Pump Applications:

1. Vacuum Distillation: Rotary vacuum pumps are commonly used in distillation processes where substances need to be separated under reduced pressure conditions, such as in the petroleum, pharmaceutical, and chemical industries.

2. Vacuum Filtration: They are used to create vacuum pressure for filtration processes, such as in laboratories or industrial settings, to separate solids from liquids.

3. Vacuum Packaging: Rotary vacuum pumps are utilized in the food packaging industry to remove air from packaging containers, extending the shelf life of perishable products.

4. Degassing and Deaeration: In industries like electronics and manufacturing, rotary vacuum pumps are used to remove gases from materials, ensuring quality and reliability in production processes.

5. Vacuum Drying: Rotary vacuum pumps help in drying processes by removing moisture from materials under vacuum conditions, which is useful in industries like pharmaceuticals, food processing, and electronics manufacturing.

6. Vacuum Freeze Drying: Used in freeze-drying processes to remove moisture from perishable goods without compromising their structure and quality, often employed in the food, pharmaceutical, and biotechnology industries.

7. Laboratory Applications: Rotary vacuum pumps are extensively used in laboratories for various applications such as solvent evaporation, vacuum ovens, vacuum desiccators, and rotary evaporators.

8. Central Vacuum Systems: Rotary vacuum pumps can be used as part of central vacuum systems in large industrial facilities or laboratories where a continuous vacuum source is required for multiple applications.

Rotary Vacuum Pump Advantages:

1. High Vacuum Levels: Rotary vacuum pumps can achieve high vacuum levels, making them suitable for applications where precise control over pressure is required, such as in semiconductor manufacturing and analytical instrumentation.

2. Continuous Operation: These pumps can operate continuously without the need for frequent maintenance or downtime, providing reliable vacuum performance for extended periods.

3. Compact Design: Rotary vacuum pumps typically have a compact design, making them space-efficient and suitable for installations where space is limited, such as in laboratories or on manufacturing equipment.

4. Low Noise and Vibration: Compared to some other types of vacuum pumps, rotary vacuum pumps generally produce lower levels of noise and vibration, contributing to a quieter and more stable working environment.

5. Oil-Sealed Variants: Oil-sealed rotary vacuum pumps offer effective sealing against air leakage, ensuring a consistent vacuum level and minimizing contamination in sensitive processes.

6. Versatility: Rotary vacuum pumps can handle a wide range of gases and vapors, making them versatile for various applications across different industries, from distillation and filtration to freeze-drying and coating processes.

7. Ease of Maintenance: Routine maintenance of rotary vacuum pumps typically involves simple tasks such as oil changes and filter replacements, making them relatively easy to maintain compared to some other vacuum pump types.

8. Cost-Effective: Rotary vacuum pumps often offer a favorable balance between performance and cost, providing efficient vacuum solutions without requiring significant upfront investment.

9. Suitable for Harsh Environments: Some rotary vacuum pumps are designed to withstand harsh operating conditions, such as high temperatures or corrosive environments, making them suitable for demanding industrial applications.

10. Scalability: Rotary vacuum pumps are available in a wide range of sizes and capacities, allowing for scalability to meet the specific vacuum requirements of different applications, from small laboratory setups to large industrial processes.

Rotary Vacuum Pump FAQ:

Q. How does a rotary vacuum pump work?

Ans: Rotary vacuum pumps work by using rotating vanes or blades to compress gas inside a chamber and then expel it through an outlet, creating a vacuum in the process. This action continuously removes gas molecules from the system, lowering the pressure inside to achieve the desired vacuum level.

Q. What are the main components of a rotary vacuum pump?

Ans: The main components of a rotary vacuum pump typically include a rotor with vanes or blades, a stator, an inlet port, an outlet port, and sometimes an oil reservoir and sealing mechanism.

Q. What are the different types of rotary vacuum pumps?

Ans: Common types of rotary vacuum pumps include oil-sealed rotary vane pumps, dry screw pumps, and rotary piston pumps. Each type has its own advantages and is suited for different applications.

Q. What are the typical applications of rotary vacuum pumps?

Ans: Rotary vacuum pumps are used in various industries and applications such as distillation, filtration, packaging, degassing, coating, drying, and laboratory processes requiring vacuum conditions.

Q. How do I choose the right rotary vacuum pump for my application?

Ans: Factors to consider when selecting a rotary vacuum pump include the required vacuum level, pumping speed, gas compatibility, operating temperature, maintenance requirements, and budget constraints.

Q. What maintenance is required for rotary vacuum pumps?

Ans: Maintenance tasks for rotary vacuum pumps typically include regular oil changes, cleaning or replacing filters, checking seals and gaskets, and inspecting for wear or damage. Manufacturers provide specific maintenance guidelines for each pump model.

Q. Can rotary vacuum pumps handle liquids?

Ans: Rotary vacuum pumps are generally not suitable for handling liquids directly as they are designed to handle gas or vapor. However, they can be used in processes involving liquid evaporation or condensation under vacuum conditions.

Q. How long do rotary vacuum pumps last?

Ans: The lifespan of a rotary vacuum pump depends on various factors including operating conditions, maintenance practices, and the quality of the pump. With proper maintenance, rotary vacuum pumps can last for several years or even decades.

Q. Can rotary vacuum pumps be used in hazardous environments?

Ans: Some rotary vacuum pump models are designed to meet specific safety standards and can be used in hazardous environments with appropriate precautions and safeguards in place. It's essential to consult the pump manufacturer's specifications and safety guidelines.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese